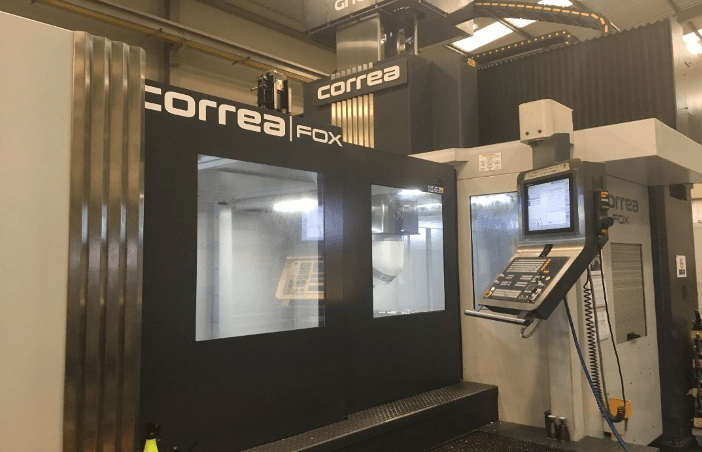

Machining

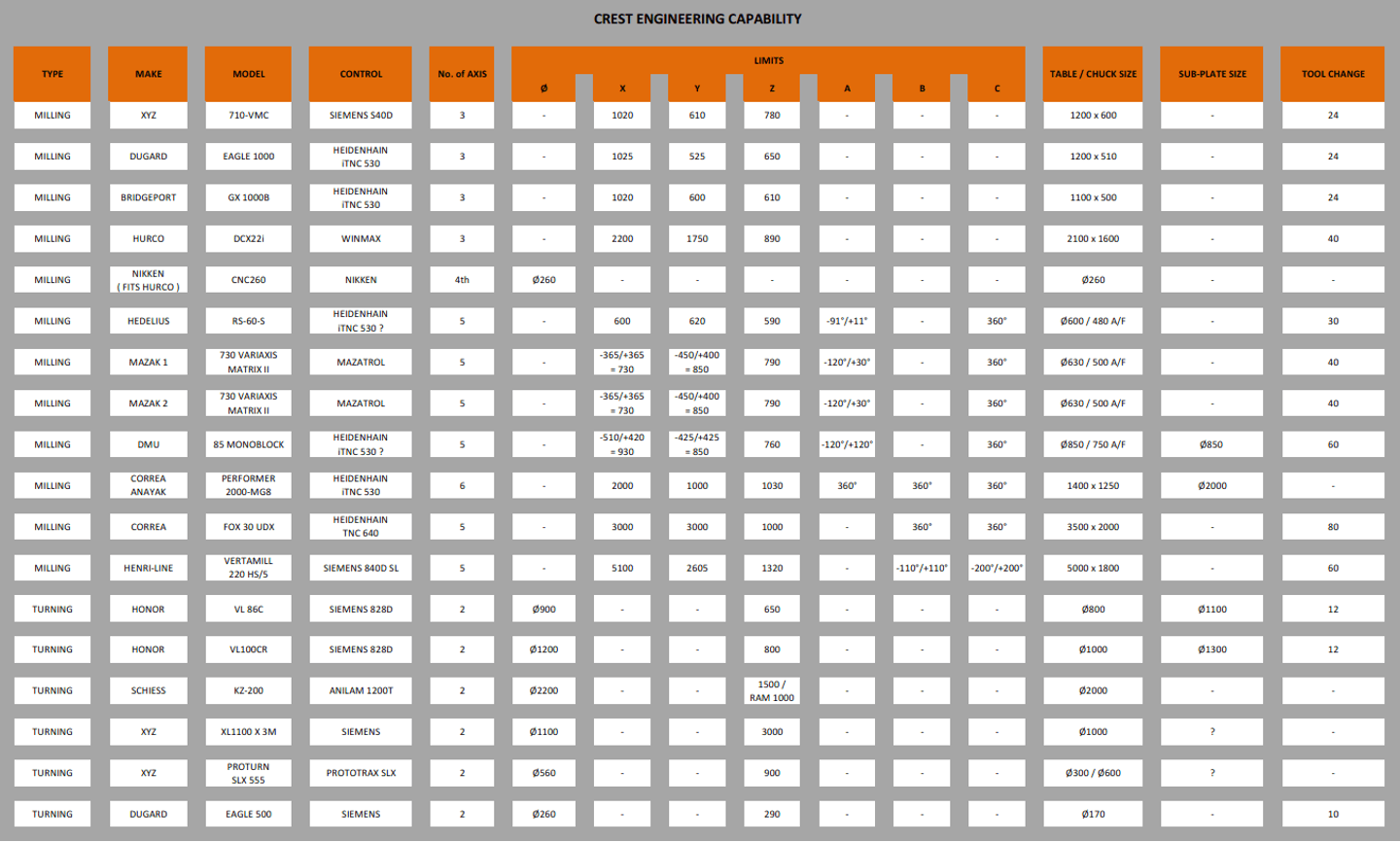

Crest Engineering can offer up to 1600 manufacturing hours per week across our wide range of CNC turning and milling machine centres.

Crest Engineering have extensive experience in supporting our customers’ machining requirements across development, production, and tooling applications.

A total manufacturing solution you can rely on.

- Constant commitment to reinvestment and development of metal cutting technologies

- 1600 machine hours per week across 3/4/5/6 axis machine tools

- Precision turning capability and gas turbine module assembly experience

Working with our manufacturing engineers to support

- De-risking the manufacturing process

- manufacturability assessment

- highlighting risks and opportunities

- Concurrent manufacture aligned to design maturity

- Material selection

- availability

- obsolescence / secure supply routes

- Geometric Dimensioning and Tolerancing (GD&T)

- Fixed process control of manufacture

- Welding process and suitable qualifications and procedures

- Definition of special process requirements

We operate Delcam PowerShape® and PowerMill® software to create our NC programs, supported by Vericut® software to ensure everything is correct prior to first metal cutting – evidence of our ‘right first time’ manufacturing process methodology.